|

|

|

Mosin Nagant M44 Sporter Page 10

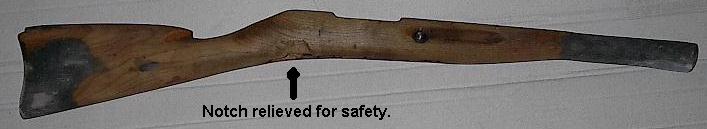

Since all the metal work is now complete, it was time to get back to the stock. I had to use a rasp file to relieve the area for the new installed safety.

Now after checking and rechecking the fitting of everything, it was time to apply the camo fabric. The choice of fabric isn't actually that important. However, when it's done, the fabric will sort of change colors. If you decide to try this yourself, just take a scrap piece of fabric, soak it in water and that is basically the color, your stock will be, when complete. Since the stock isn't a truely flat surface and irregularly shaped, a few peices will be needed. It's easier to use a bunch of smaller pieces than it is to use 3 or 4. The main idea is to hide the seams as best as possible. You can let the seams overlap one another by 1/8-1/4 of an inch. I wouldn't worry too much about trimmimg the area of the trigger guard, receiver or barrel channel. Those areas can be trimmed after the first coat of fiberglass is applied.That is why it's important to make all the necessary cuts and/or patterns prior to adhering the first piece of fabric. The most difficult area for me was the wrist area. I should've used 2 smaller pieces here. However, I didn't and it was too late, so I had to make due and repair the area a few times, until it was right. It also helps if your stock is undersized. It doesn't have to be perfect, but undersizing the stock in all areas, does help. The fabric and fiberglass will make up the difference.

The items I needed to camo the stock can be bought at any hardware store. First you obviously need fabric to your liking. You'll need a pair of scissors and/or a razor blade to cut and trim the fabric. A square yard is enough to do a couple of rifles. You will need a good quality paint brush. The paint brush is used to apply the fiberglass resin. I used small plastic dixie cups to mix the resin and hardener together. I chose the smaller dixie cups because I didn't want to mix too much and waste the fiberglass. However, as the fiberglass hardens, it can each through the dixie cup, so watch what you place it on. To mix the hardener and resin, you can use an old screw driver or wooden stick. You will also need a couple of sheets of sandpaper. Nothing special on the sandpaper. I used coarse, medium and fine grits. A rifle cleaning rack will also come in handy, but anything that will keep the wet fiberglass from touching anything else, is sufficient. I chose to use Evercoat Clear Fiberglass Resin. There are other products (epoxies) on the market, but I haven't tried them yet. They will be for the next project I'm working on. You will also need some clear liquid hardener and some acetone. The acetone is used to clean your brush in between applications and anything that might have gotten fiberglass on it (ex: your hands). A decent pair of rubber gloves is a help too, but I didn't use any.

Although, I didn't take pictures between the various applications of the fiberglass, it's pretty straight forward. First thing to do is to make sure the stock surface is free of any grease or dirt. There are numerous ways to do this. I chose to use cheap oven cleaner. I applied it outside, then let it set for about 20 minutes. I then wiped off the grease that drawn out of the stock. I did this at least 3 times. I then let the stock dry over night. Then when it was dry, with a clean rag, i wiped the stock down with acetone. After looking the stock over and not seeing any really smooth surfaces or any dirt, it was time to apply the fiberglass. I mixed up a small amount of fiberglass resin and hardener. with the paint brush, I liberally applied the fiberglass to the areas where the fabric was going to be. It's best to start out on one side of the stock. It makes the job a lot easier. Moreover, when mixing the resin and hardener, it's easier to mix smaller amounts, so you don't waste it. Just mix what you need as you go along. When the fiberglass was tacky, I then got the appropriate cut piece of fabric and applied the mixed fiberglass to the back of the fabric. Again using the paint brush. After the fabric is thoroughly coated, apply it to the stock. Now is is the time to make any adjustments, you may have to make, in the positioning of the fabric. This is done over and over again to each piece of fabric, for the side you are doing. You just want to make sure that all the fabric that needs to be adhered to the stock, is actually touching the stock. If for whatever reason, the fabric isn't staying exactly where you want it, you can use rubberbands or small tacks, until the first coat dries. After the first side is dry, you would do the exact same procedure on the otherside of the stock. After both sides are done, there might be small places not covered. You can now remove the rubberbands and/or tacks you may have used. Next you might want to knock down any high spots in the fabric or fiberglass. Sometimes the fiberglass may run and then harden. You can do this with any or a combination of a razor knife, file and/or sandpaper. Now is also the time to trim the fabric around the receiver, barrel channel and trigger guard, if you chose not to cut these out prior to applying the fiberglass. Now is also a good time to look around the stock to see if any spots were missed by the fabric. I'm not a seamstress, so my fabric cutouts weren't exactly perfect. If there are some, you can mix up a small amount of fiberglass and adhere in smaller pieces of fabric. Just try to use a portion of fabric, that matches. After that, you would then begin to mix up more hardener and resin to apply to the stock. The amount of applications vary. This is due to the fabric you may use or how thick you apply the fiberglass. I used thinner coats. After a few coats, the fiberglass will build up to where you can not feel the texture of the fabric. At this point, I would lightly sand the stock and apply a couple of more coats of fiberglass. When it's to your liking, a final sanding is required. Now the stock will appear dull or hazy. I then bought a can of matte clear Rustoleum and applied it over the stock. I'm sure there are better products out there, but that's what I decided to use. It's cheap and easy to use. I just used a couple of coats.

The pictures below show the stock after the final application of fiberglass. This is prior to final sanding and the spraying of a clear coat.